✨ Elevate your DIY game with Stone Coat — where art meets durability 🍽️

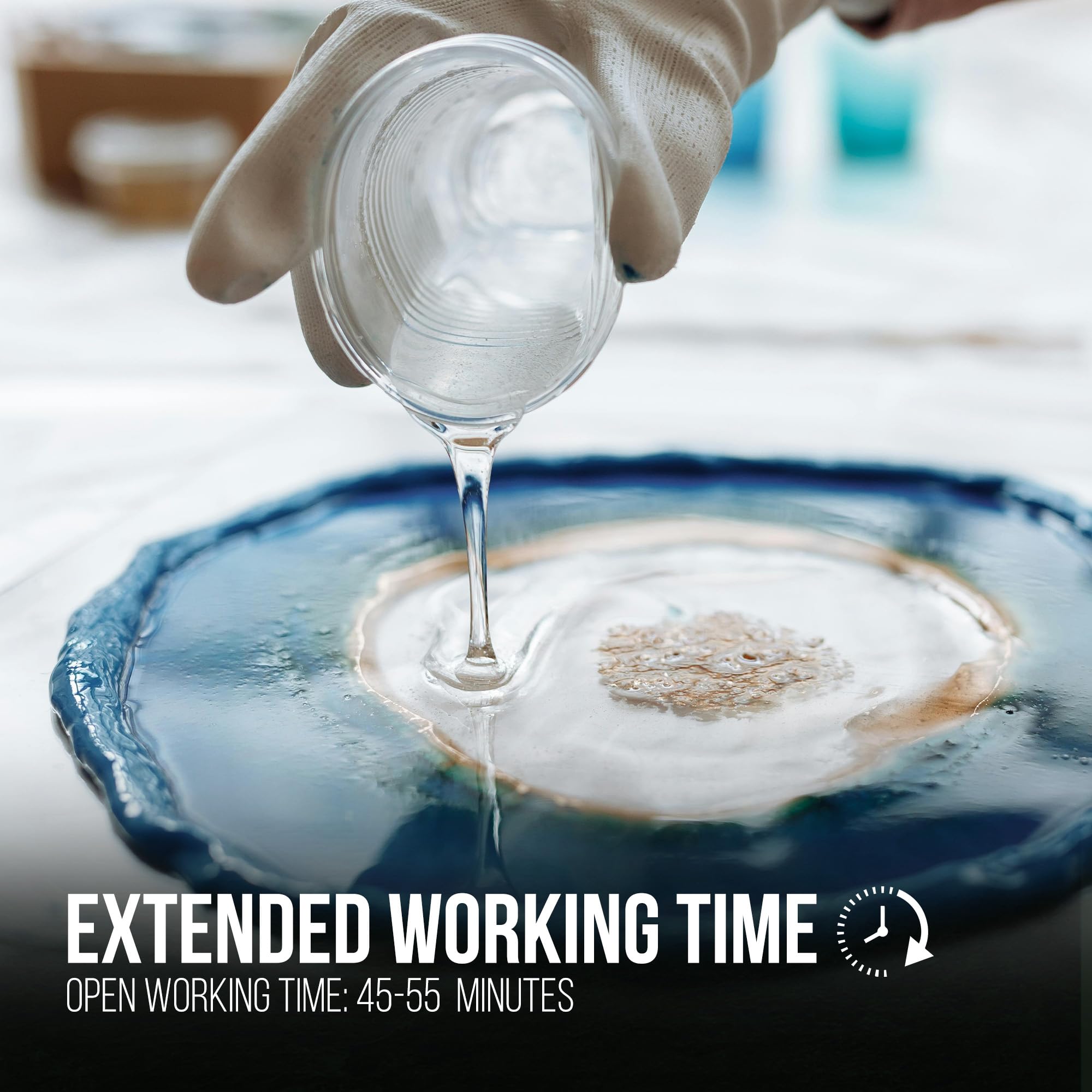

Stone Coat Countertops Art Coat Epoxy Resin Kit is a premium, zero-VOC, food-safe epoxy resin designed for artists and DIY enthusiasts. Featuring UV resistance, extended working time, and compatibility with various art mediums, it delivers a durable, heat- and scratch-resistant finish ideal for countertops, coasters, and creative projects.

A**N

Great epoxy

Great epoxy. The only epoxy product i use!

L**O

Easy to use

This product was easy to use. I was glad I wouldn’t need a respirator but was ready with gloves and a mask.I prepped my surfaces and mixed the epoxy. I added diamond dust, colored dye, and spray paint. I used the blowtorch. I scraped the drips. And then I held my breath overnight and hoped it would set up. The next day everything had hardened so It’s a win. If you’re going to use this I suggest watching several videos and making sure your temperature And humidity are right. I have since realized it definitely needs a coat of sealer. I had a pretty flat end result the first few days (I looked it over a bunch just being a harsh critic of any of my own projects) and several weeks later I feel like either bubbles have worked their way to the surface or I have several small gouges. Despite this-the overall appearance is great and I’m satisfied with the end result. But I’ll definitely be adding a clear coat in the near future.

E**Z

Amazing product!

Love it! Durable, dry hard as a rock amazing how my project came out, easy to clean.

R**K

Amazing results!!

I love this stuff! So easy and forgiving. Literally anyone can do it. Do happy with the outcome.

A**R

Great epoxy

Any brand of epoxy is not something to play around with unless you have watched multiple videos and have all the right tools and the right environment to use it in . It has to be done indoors and has to stay a constant temperature of 75° - 80° or you will be sorry . *** Read the directions and do not think for any reason that you can deviate from them one single bit or you will either ruin what you are trying to do or you will have to start all over again after a long messy clean up . And no matter what type of material you are using this for you can not just bring it inside and pour the epoxy on it . You have to let the materials acclimate to 75° - 80° for at least 24 hours and if it's a thick slab of wood you should get it kiln dried . Just because you left a thick slab of wood outside under a roof that doesn't mean it's seasoned not to mention that it will have small wood bugs inside it and they will drill / bore back through the epoxy weeks sometimes months after the epoxy has been poured unless you kill them by having it kiln dried . You should have it kiln dried then have it wood mizered to make it perfectly flat if desired , then acclimate it for at least 3 days then check it for flatness again , and if it hasn't changed shape then prep it per the directions , then pour it . And even after all that you need to know that you can not take a slab of wood that has been in a 75° - 80° room and then coated in epoxy , then put it outside in any temperature not in that range . It would have to be slowly introduced to lower or higher temperatures gradually or it will do a number of different things that are all going to ruin the glass like look you want and you will have to do it all over again . Epoxy is not a easy project no matter what videos show or say if not done correctly .

M**S

More difficult to work with than other resins, plus poor heat resistance and customer support

I used Stone Coat Art Coat to coat my acrylic-painted 4" ceramic tiles to be used as coasters. This resin failed in most of the ways I'd hoped it would have worked. Especially for it being one of the most expensive resins available.I mixed the hardener & resin 1:1 by volume (not by weight) for 4-5 minutes. Like others have said, there were a lot of bubbles - more than other resins I've tried. But after coating my tiles, I made the bubbles disappear by quickly waving a kitchen torch over them. After curing overnight in a room about 70-75 degrees, the resined surface was hard to the touch, but I let it cure for a full 30 days before trying to use it as a coaster.While coaster was fine to use with any cold drinks, Stone Coat Art Coat could not hold up to a single mug of freshly-poured coffee sitting on it's surface for 5 minutes. In that short time, the resin re-softened and left thin but permanent mug rings damaging the otherwise glass-like surface.After reading Stone Coat's advertised heat-resistance of 470 degrees I wondered if I'd done something wrong. Coffee is only brewed at 180-200 degrees, and the outside of a mug would be an even lower temp than that.So I got on Stone Coat's website to ask for help. Using their form request on their Contact Us page, I stated the problem I've stated here, and asked if I'd done anything wrong or if there was any way I could achieve the heat resistance they advertise.Silence. They never replied, and I made sure to check my spam and all other places an email might get misdirected. Nothing.So my low rating reflects the results of an expensive product that does not work as advertised and a company with poor (or non-existent) customer support.

N**A

Like the outcome

Came out great the 2nd time around . Messed up on the 1st try .

M**L

So easy

I love the way my table look, this product is easy to work with and you have spectacular results, in person the table look much betterThe videos of the stone coat guys helped a lot

Trustpilot

1 month ago

3 weeks ago