Servicios al cliente

Sobre nosotros

Copyright © 2025 Desertcart Holdings Limited

Desert Online General Trading LLC

Dubai, United Arab Emirates

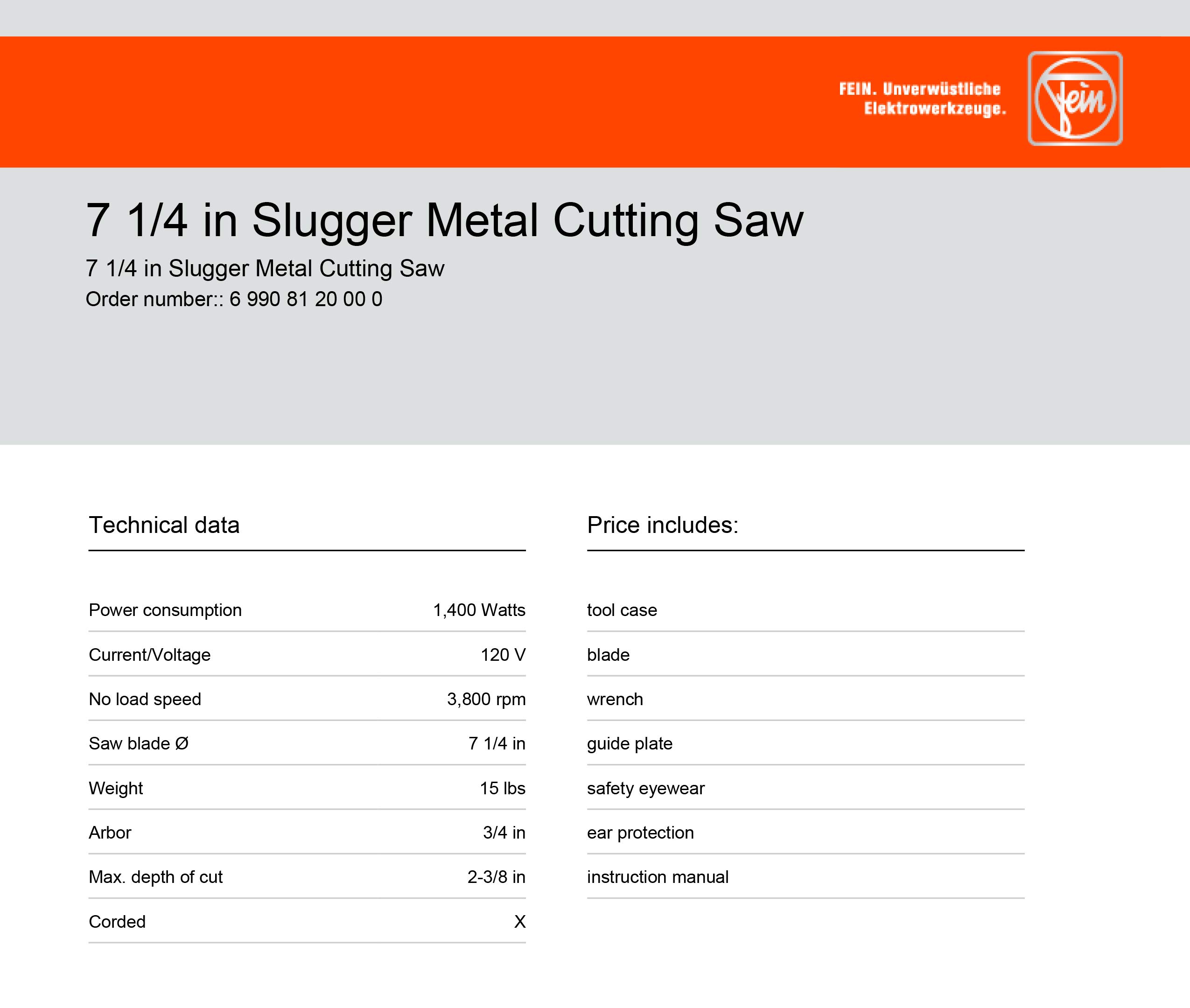

The FEIN 7.25" Slugger Metal Saw is the high performance, durable solution for metal cutting. Unlike other metal cutting options, the 7.25" Slugger Metal Saw leaves a workable edge when cutting steel plate, square tube, angle, pipe, and tube. A specially designed cover to collect virtually all chips and sparks allows the 7.25" Slugger Metal Saw to perform quick clean cuts including the ability to bevel cut up to 45 degrees. With an integrated laser guide, the 7.25" Slugger Metal Saw has the capability that no other metal cutter can offer. The FEIN 7.25" SLUGGER Metal Cutting Saw is an versatile, high quality power tool.

A**N

BEYOND ALL EXPECTATIONS!! WOW!!

Purchased the Jancy Slugger off of Amazon relying on the good product reviews. I didn't really know what to expect as the only other cutting tool I have in my shop is a bandsaw and of course angle grinder cut off wheels. This saw is so spectacular that you'll seriously wonder how you got by without it. IT IS A GAME CHANGER!!First let me say that setup out of the box is very easy and simple. There's not too much to the saw, but do read the instructions as it gives you orientation guidelines for cutting metal. The blade it comes with is for cutting mild steel only. There are optional blades for cutting ferrous materials and stainless steel. Cold saws aren't great at cutting stainless so if that's your need I'd go back to a bandsaw. For everything else this is the saw!For all the complaints you read on amazon about various saws and their vice problems it's great to find a saw that has an excellent vice. I've had absolutely no problems with the vice on this saw and it's extremely strong. Your work is not going anywhere. The amount of safety and expertise that has gone into this saw is apparent out of the box. There are nearly a dozen different metal cutting saws on Amazon, many are cheaper but they are all inferior to this product. First let me say that you definitely need the 14" capacity as it comes in very handy when cutting deeper stock which is very likely during fabrication. Secondly I've found the blade length on this saw to be excellent. As long as you don't force it and let the blade cut through the steel gently then you'll get an enormous amount of use out of each blade. Be careful to orient the steel properly in the vice. You want to avoid cutting large flat surfaces whenever possible. Flat stock should be held upright. You will need to use hearing protection as it is loud, but no real louder than any other chop saw out there.This saw will cut anything you can fit under the guard. No problems cutting 1" Square or 2" Square or greater material. I just cut a bit then bring the saw a little out of the material to keep the blade cool when cutting super thick material. It can cut several times faster than a bandsaw which greatly reduces fabrication times. You can also cut literally any length off the material without deflection, cutting 1/16 or 1/32 off some material is no problem at all. And there is no heat in the blade nor heat in the material whatsoever. The cut is bright and mirror smooth with virtually no clean up. There's also no smoke or dust from the saw which is of incredible benefit. All the hot cut saws produce nasty dust and smoke from the wheel that is a known cancer causing carcinogen. With this saw there is none of that, only tiny little chips that are very easy to clean up and are too heavy to get airborne.One of the first heavy jobs I did with my saw was cut hinges for my shop doors. They are 5/16's thick plate steel that are 5" wide x 10" long. This is some hefty material. Did I mention I needed a dozen of them! The saw made short work of all these cuts and the blade is still razor sharp. Truly amazing. I'd be there literally all day to cut this material on my bandsaw and the Slugger did it in about 30 mins. You do still have to take time to align the cuts. ;-)Here in the picture you can see the stack of plates. If you add up that material it's 5" wide x 4" thick! Now that's one hefty brick of steel the Slugger cut through without issue. Blade still sharp as the day I got it. Buy the Slugger, you won't be disappointed. All the other cheaper saws are junk.The only con I found with the saw is that the hold down mechanism is antiquated. Basically there is a chain and a hook to hold the saw down when not in use. Why they couldn't just figure out a locking pin is beyond me. But I rarely lock the saw down unless you're going to move it or travel with it. The guards prevent you from contacting the blade.All in all I would give this saw a 10/10 for it's usefulness, it's precision cutting, it's small form factor, the depth of cut, and the longevity of the blade. The Slugger really knocks it out of the park. It really changed the way I fabricate and sped up my pace dramatically.UPDATE 3/23/18 I think I finally started to slightly dull the blade (though still has some use left in the blade) after six long months of cutting endless amounts of 5/8's blade, 1"-2" solid bar, rounds, angle iron, tubing and everything else that would fit under the guard. You can get blades for $80-$150 depending on the blade. Certainly worth the money when you can get hundreds of cuts out of it. Also much easier to change a rotary saw blade then changing blades on a horizontal or vertical bandsaw imo as guides always need to be readjusted on bandsaws as well as tracking and down feet, etc. Jancy Slugger is the future of metal cutting and now is the corner stone for my shop. My next purchase will be some sort of table to mount the Slugger too.

R**K

Solid saw that performs well

I have had this for a few months now and am pleased to say that it is a terrific saw. The manufacturing is well done, as is the design. Cuts like magic. I have cut piles of 1" to 3" square tubing, flat bar, 1-1/2" pipe and angle iron with it and it has saved me enough time over cutting with my horizontal band saw to have paid for itself already. Be aware that it throws a lot of chips when cutting and the chip catcher doesn't catch that much. My shop looked like a glitter bomb went off in it at first, but now I have set up some containment and a larger chip tray and am very happy. Also be very careful when cutting short pieces as the kickback can hurt the blade and can also be dangerous. This is especially true when cutting at an angle. I looked at several different model saws, talked to people who use them, and read a lot of reviews before I settled on this one. I believe that I made the right choice.

J**T

$400 worth of blades later, I give up...buyer's remorse.

I noticed from watching different Youtube videos that different fab guys nowadays are going with the cold cut saw so I figured it would be worth it to get one and perhaps replace my band saw. I've worked with a wide variety abrasive cutoff wheels and bandsaws in fab shops for 20+ years and very familiar with how to run them at the proper pressure needed to get the max life and efficiency out of blades.The cost of this cold cut saw itself is lower than a good band saw so that factor is appealing. However, the blades cost over $100 each compared to $30 for my band saw. We use the cold cut saw mostly to miter cut 2x2x1/8" tubing.The saw blades cut great for the first 10 or 15 cuts but begin to die off surprisingly quickly. I've tried several different pressures between light and medium but always careful to apply steady and even pressure as with any saw blade.After about 25-30 cuts we really have to crank down on the saw as it begins to go nowhere at the first part of the cut, the blade just spins on top of the tube throwing very little shavings and makes a red hot spot in the metal.The blades begin to warp from the heat of the hot spot, once the top of the tube is cut the vertical sections go quickly still, on the bottom section of tube the saw blade begins to heat up more noticeably.At this point so much pressure has to be applied to the blade to get it to cut that the motor begins to smell like it's on the verge of overheating.The downward circular pressure of the spinning blade against the tube causes the blade to draw the tube closer towards the blade; throwing the blade towards the right side of the blade slot until it's actually cutting the slot wider.In order to attempt to try to hold the tube in place, the crank handle has to be tightened down against the tube so much that it can throw the fence out of alignment if it's not cranked down super tight.Even tightened down until what feels like near the breaking point, the crank loosens by itself from the vibration of the saw, then tube is loose.Another nuisance is that the saw never sat flat from the beginning. Always had to use a shim to get it to sit flat.The saw feels well made, if the blades didn't die so quickly it wouldn't require massive amounts of downward force to power the blade through the cut.Also, these are NOT burr free cuts! Any round DOM tubing always leaves a burr on the bottom, even with a brand new blade. The square tubing actually is entirely burr free for the first few cuts but then begins to leave progressively larger and nastier burrs. So this is certainly false or misleading advertising and I will upload photos.All in all, I definitely regret buying this saw. If I can only make 50 cuts with each blade that will cost me nearly $5,200 a year as compared to spending less than $150 a year on band saw blades.

D**T

Excellent saw... for me anyway.

This is the first metal saw (other than a bandsaw) that I’ve ever used, and I’ve only taken a few cuts with it.It is phenomenal. I have the 7-1/4” and it has far exceeded my expectations of how well a saw would cut through metal. While I haven’t used a dry cut before, I’ve made more cuts with a circular saw than a guy could want and this cuts probably about as easy as my Dewalt cuts through a 2x4 or plywood.I read some complaints about theirs arriving damaged, mine was perfect. I also looked on some message boards and was anticipating the build quality to be about what you get at a box store or maybe with some freight you got by the harbor. Not the case. Seems to be really well built. I couldn’t be more pleased.

A**R

just how tough is this saw

after checking many reviews i bought one and was expecting good. well day one torture test (new table for drill-press) 3/4" by 6" bar vary few sparks just let the weight of the saw do the work clean polished edge square. little warmth but nothing you could not pick up bare hand. and yes it will miter cut too this saw is the real deal.

Trustpilot

Hace 3 semanas

Hace 5 días