Servicios al cliente

Sobre nosotros

Copyright © 2025 Desertcart Holdings Limited

🎯 Print Bold, Print Fast, Print Flawless – The Red Max Revolution!

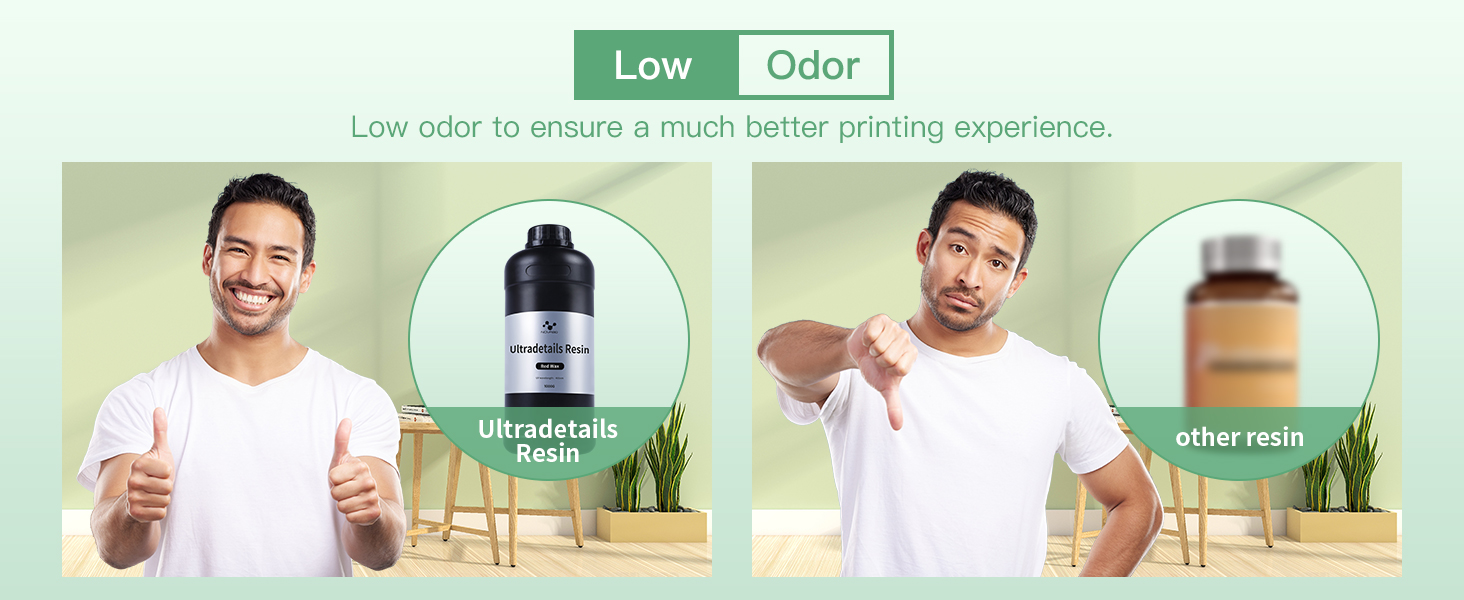

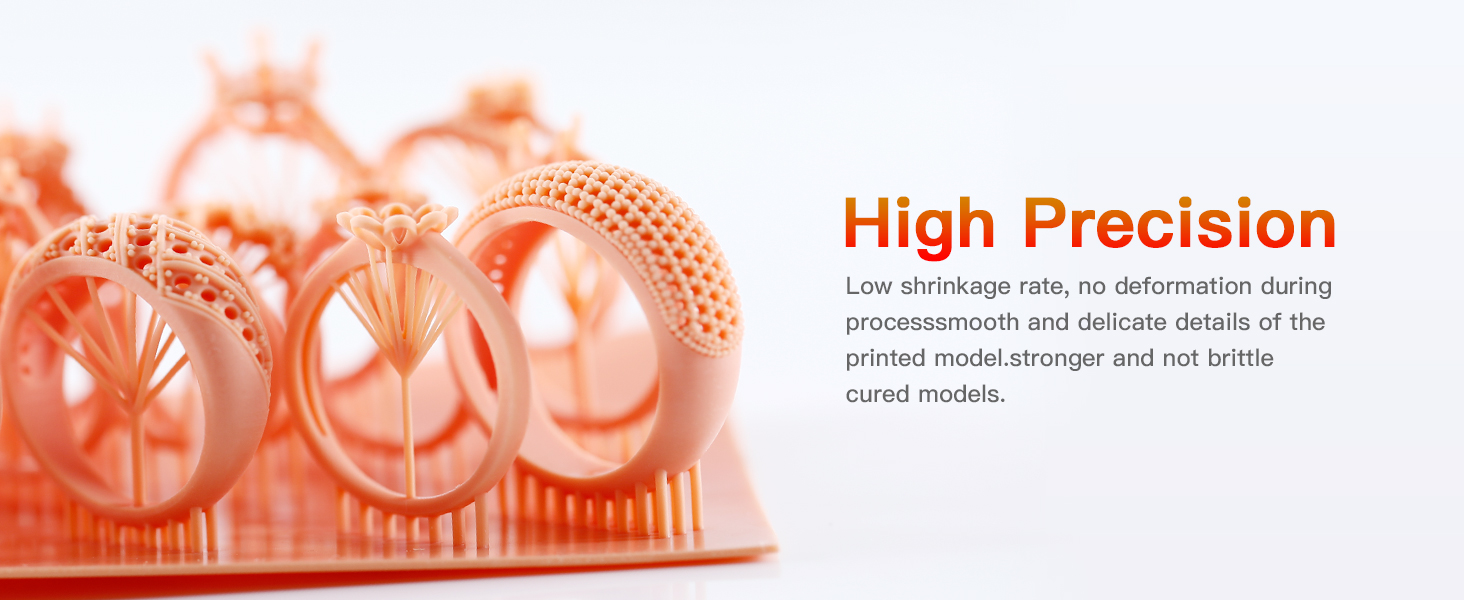

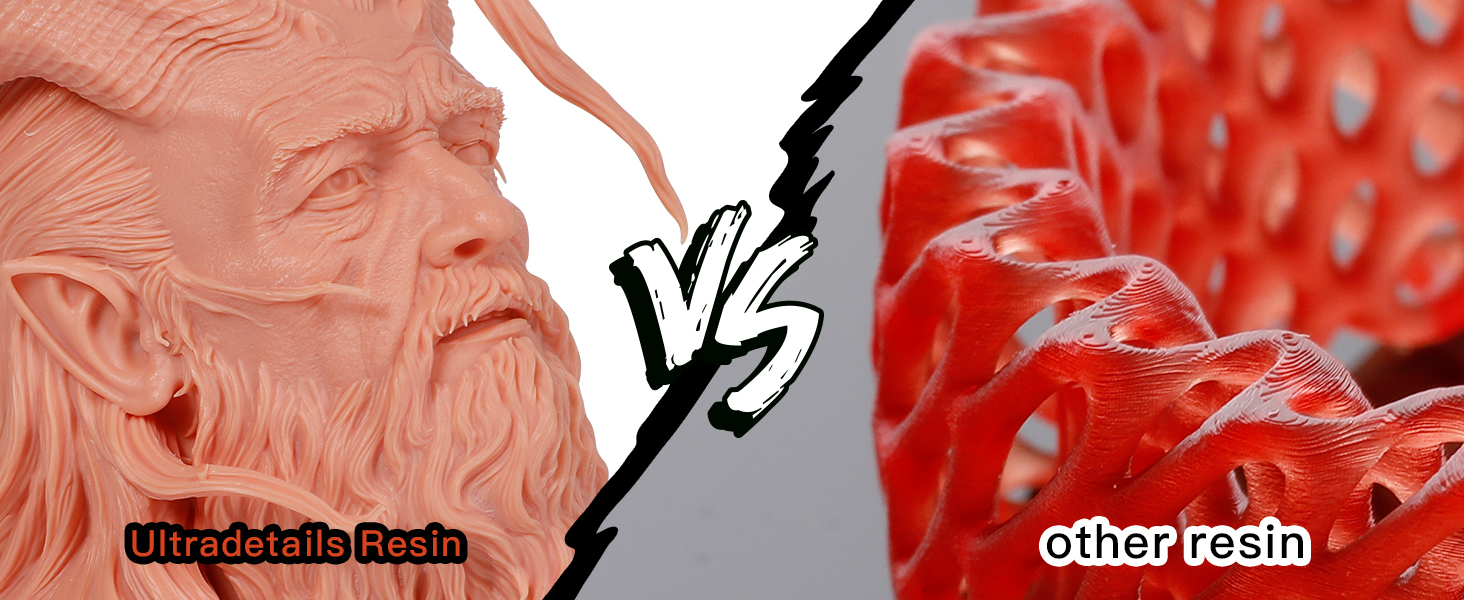

NOVA3D Red Max Resin is a 500g fast-curing, 405nm UV photopolymer resin engineered for high precision and low shrinkage. Compatible with 4K/8K LCD, DLP, and MSLA 3D printers, it delivers vibrant, fade-resistant red prints with minimal odor and easy post-processing. Perfect for professionals and hobbyists seeking reliable, detailed, and visually striking 3D prints.

| ASIN | B07ZD47P6Q |

| Best Sellers Rank | #742,190 in Industrial & Scientific ( See Top 100 in Industrial & Scientific ) #539 in 3D Printing Liquid |

| Date First Available | March 28, 2020 |

| Item Weight | 1.1 pounds |

| Item model number | US-204000RD510 |

| Manufacturer | NOVA3D |

| Package Dimensions | 7.8 x 3.3 x 3.1 inches |

G**R

BEAUTIFUL Color and translucency, flawless prints!

I truly could not be more impressed with this resin - HIGHLY RECOMMENDED. The orange color is great for my purposes and it's water-washable so I don't have to use the intense 90+% Isopropyl Alcohol, which is often hard to come by. If you're living that IPA lifestyle, you can now stop because this resin is the ANSWER!! I use PTFE oil on my FEP film on all prints now as well and it works beautifully with this resin as well. Literally I've had ZERO failed prints on my Elegoo Mars 2 Pro and slicing in Chitubox using the settings shown in the last two images. Don't think twice - this resin is FABULOUS.

A**R

Amazing resin Easy to use

This resin works very well. I have had hardly any failed prints. Compared to other much more expensive castable resins this is my favorite. What I mostly like about this resin is that It’s not too sensitive about the built plate being slightly too close or too far away from the LCD and I have never had a print fall off of the build plate during printing. I recommend it to everyone and I just ordered it again.

H**H

Terrible

Either this resin is junk, or it is totally not compatible with my printer (tried multiple settings, getting zero bed adhesion) Printer working fine with other resin, so issue is with this.

T**W

UPDATE: WILL NOT WORK (well) WITH PLATINUM SILICON MOLDING COMPOUNDS!!!

FINAL UPDATE: Here is my final procedure for best results in using this resin with platinum molding compounds. I hope this helps! 1. Wash, wash, wash your model to remove all traces of uncured resin. This resin only worked well for me with platinum silicone molding compound after I washed as follows: * Rinse in 70% IPA bath FOR 30 seconds. Remove from bath. * Place in an ultrasonic cleaner w/ a fresh charge of new, unused, 99% IPA (ethanol or a lower concentration would also probably work but I didn't test it) and run for 20 minutes w/o heat. (NOTE: If you don't know what you're doing with an ultrasonic cleaner and you use a flammable liquid you may -- no, you will eventually -- burn your house down. DON'T DO IT IF YOU DON'T KNOW THE APPROPRIATE SAFETY PRECAUTIONS AND DON'T HAVE THE PROPER EQUIPMENT NECESSARY FOR USING YOU ULTRASONIC CLEANER WITH FLAMABLE SOLVENTS!!!) 2. Once washed properly, cure FULLY and then some. I cured mine 20 minutes per side under water with a high intensity UV light. (NOTE: the more you cure the resin, the more brittle it will become. Plan for that.) 3. Once the model is in the silicone compound, cure for at least 8 hours. Then, place in an oven and bake at 150F or 66C for at least 2 hours. For extra fine detail, be careful when you unmold. Some of the silicone compound in the fine recesses may still be soft. W/ fine detail, bake in an oven at the same temperature for another hour after unmolding. All of this may seem complicated, but it beats waiting 7 - 10 days to unmold as in my second update, below. Best wishes for your successful projects! SECOND UPDATE: Well, I got this stuff to work w/ a platinum silicon molding compound. BUT, I had to let it cure for a week to ten days (rather than the typical 8 hours) depending on the level of detail in your model. I don't know if the extra cure time will work for all platinum silicon compounds, but after a week to ten days, it worked with this stuff: https://smile.amazon.com/gp/product/B06XBRGGZ3/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&psc=1 Use a different compound and YMMV. I raised this from 2 stars to 4 because I did get it to work for its intended purpose. One star off for not explaining the problems w/ platinum silicon compounds and the exceeding long cure time. However, the detail produced is the best of any resin I've tried and I'm willing to wait the week (and overlook the manufacturer's negligence in failing to test this product w/ a molding product that most will purchase this resin to use). If a week (or more) in cure time is a deal breaker for you, then don't get this stuff. UPDATE: THIS RESIN WILL NOT WORK WITH PLATINUM SILICON MOLDING COMPOUNDS! Those compounds will not cure while in contact with models made with this resin. This is a major design flaw for a resin dedicated to making molds. I've changed my review from 5 to 2 stars because of this. PLEASE BE AWARE! ORIGINAL REVIEW I'm new to resin casting, this is my first attempt AND I haven't actually cast these pieces, yet. So, please bear that in mind. That said, I've had an excellent experience with this castable resin. The detail is excellent and the supports come off w/o a hitch. The first picture is a batch of crucifixes and rosary centers that I designed as they came out of my printer (after removing the uncured resin). The second picture (please forgive the poor focus) shows the interior detail after the supports were removed from the obverse of the rosary center. Note that the support residue was removed from the inside of the center but left on the sprues. That allows you to see how the supports come off and how they clean up. The third picture shows the reverse of the rosary center and its inscription of the Ave Maria in Latin. The letters in the body of the prayer are about .75mm high and about .1- .2 mm in width. Not bad! A note on the suggested printer settings. I printed at .035. The manufacturer suggested a setting of 6.5 seconds exposure per layer with my Elegoo Mars. That setting caused some failures in the thinnest parts of the rosary center and on some supports of the crucifix. This was easily fixed by upping the layer setting to 8 seconds exposure. Also note that the supports are much easier to remove cleanly before you cure the pieces after they come out of the printer. Here were the printer settings I used with the Elegoo Mars: Layer Height - .035 Bottom Layer Count - 8 Exposure Time - 8 sec Bottom Exposure time - 80 sec No light-off delays Bottom Lift Distance - 5 mm Bottom Lift Speed - 65mm/min Lifting Speed - 65mm/min Retract Speed - 150 mm/min I hope this is helpful. Please feel free to ask questions if you have any. In all, I VERY pleased with this purchase! PLEASE NOTE: This is NOT a castable resin. It is a resin used to make silicon or rubber molds into which you inject melted wax to make your models. You then investment cast the wax models into metal. If you don't read the description carefully, you may make the mistake like I did and believe this is a castable resin. However, this isn't a bad thing. No castable resin is as good as wax. I'm actually glad I made this mistake because it forced me to create a wax mold from these models which results in better castings than I could have gotten in any castable resin.

D**D

Not for casting

NOT FOR CASTING - WILL NOT BURN OUT

A**S

Extremely Sharp Details and Easy Post Processing

As others have noted in their reviews, it is important to know right away that this is not a resin for direct casting and burnout. What it IS however is an excellent high detail resin for making masters. This resin picks up excellent details and sharp edges while still somehow having a soft feel and a little bit of flex to it. It sands and files very easily making post processing a snap If you're making silicone mold for wax injections, this is a great place to start. You need a good master to produce a good mold and this makes a good master easy to do. I did have to tweak my settings a bit from the manufacturers recommendations, but I like thin lines and crisp edges and I am also not using the Nova3D Elfin that they wrote them for. On my Voxelab Polaris, I had a little bit of difficulty getting thin sections to hold together unless I upped my exposure time. The ring in my picture is a size 6, to get the lettering to come out correctly required 10s exposures. 50um Layers Base layers 6 Bottom exposure time 50s Normal Exposure time 8s (small areas may require more exposure or they can separate)

D**D

best high-detail resin

easily the best high-detail resin Ive used. I print using a Longer Orange 30, both 50um and 25um prints are fantastically detailed and clean. Lift speed is 45mm/min for 6mm and exposure is 7s for 50um, 5s for 25um. Bottom layer count is 6 for 50um, 12 for 25um, with bottom exposure at 60s.

E**D

I dig it!!

I have done one print so far on my Anycubic Photon, and I can say this is my new favorite resin! I live the finish and the detail it holds. I used the recommended settings that came with the resin and had 0 issues printing with my Photon.

Trustpilot

Hace 2 meses

Hace 4 días